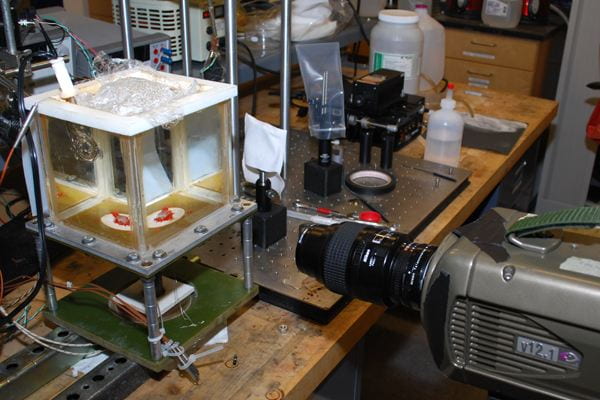

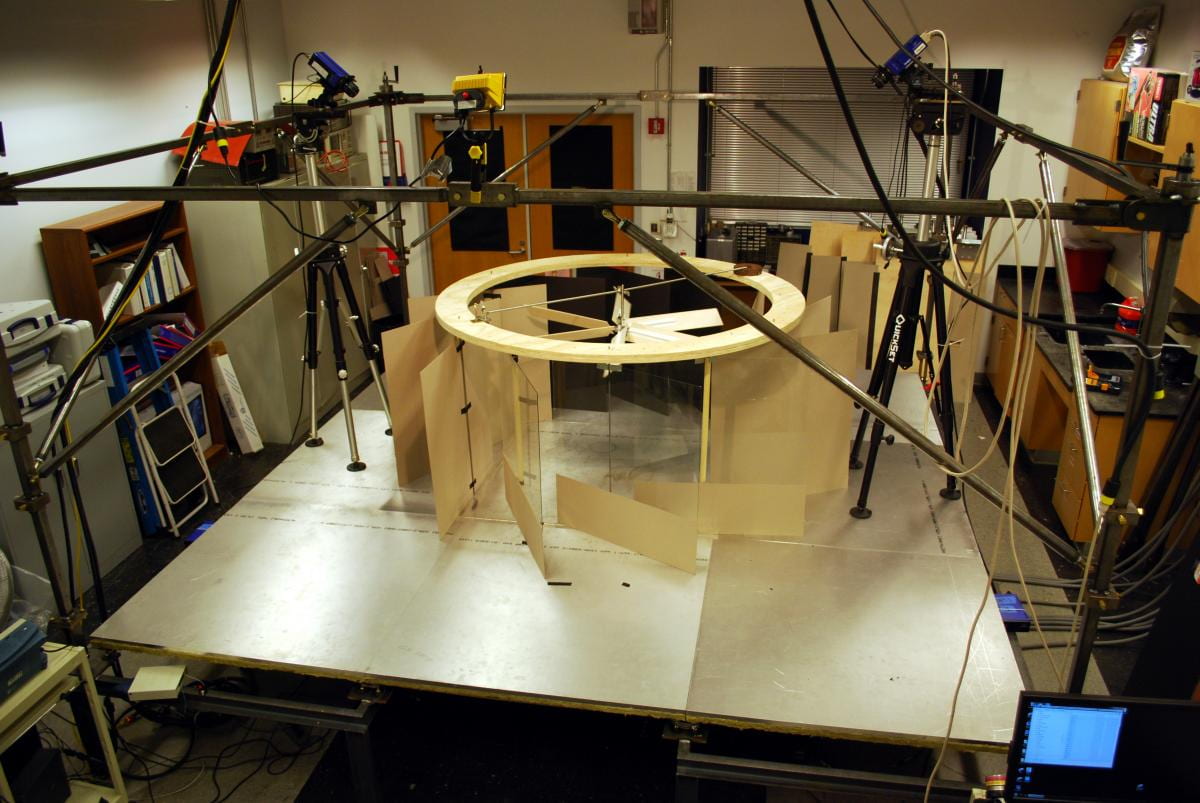

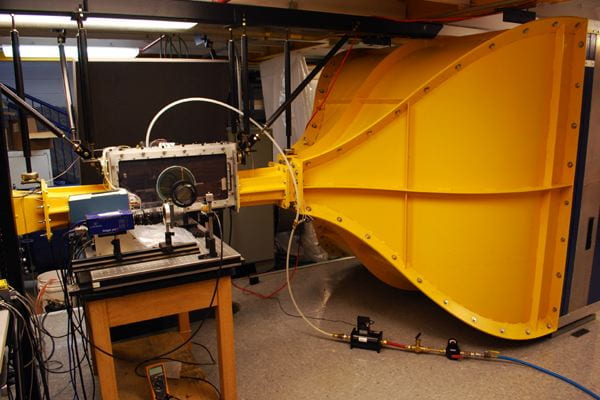

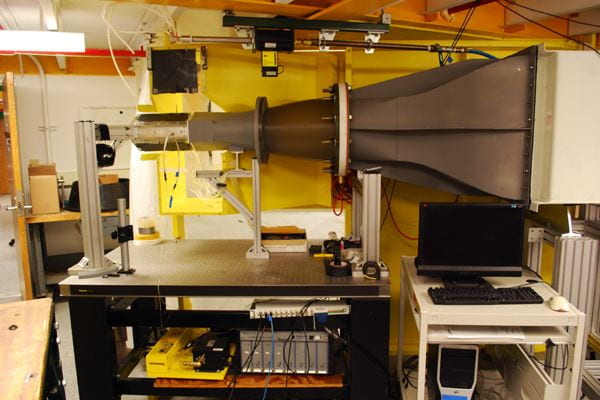

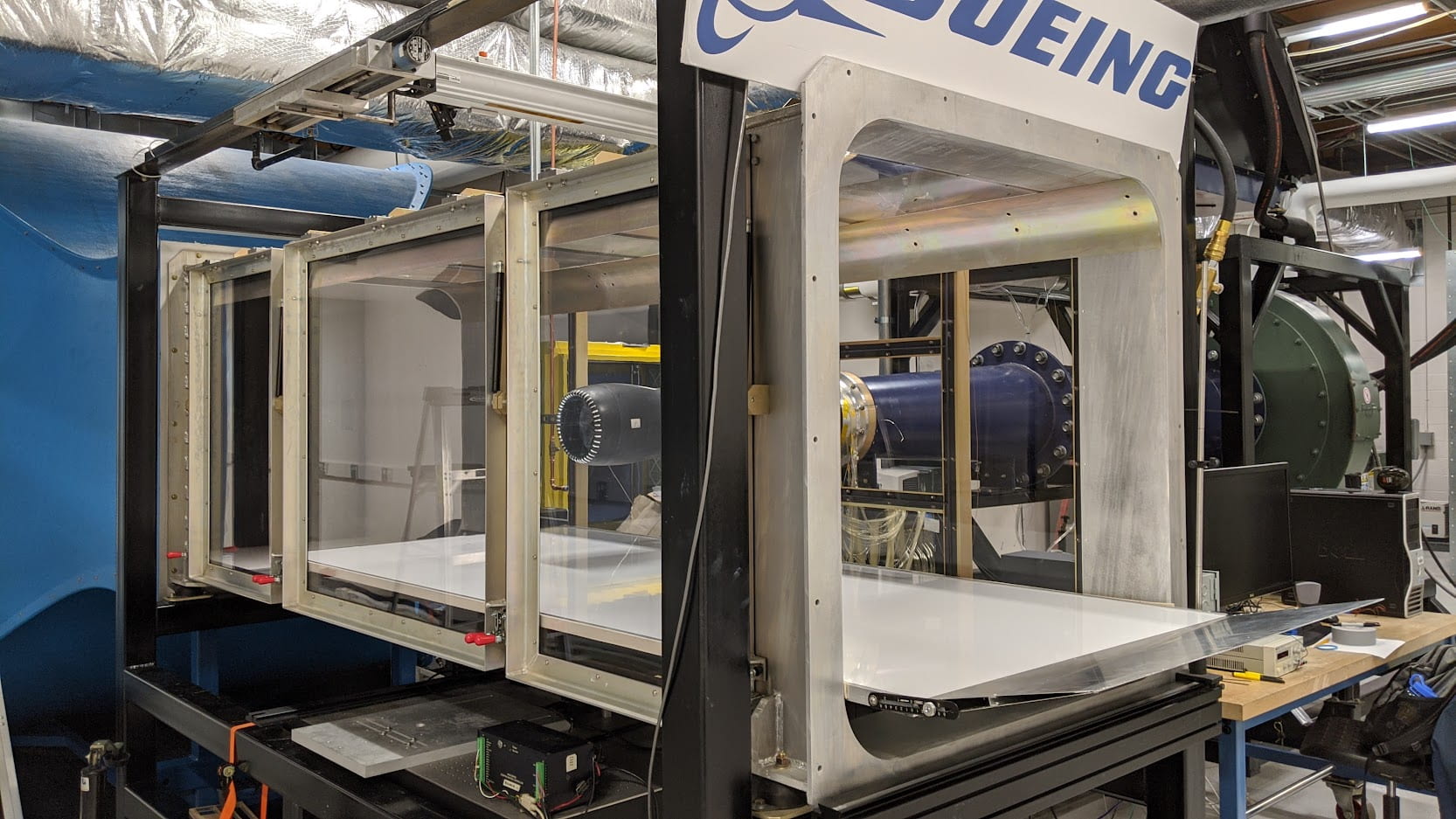

The 7,500 ft2 laboratory is equipped with state-of-the-art facilities and diagnostic equipment for research work in fluid mechanics and heat transfer of internal and external shear flows with specific emphasis on aerodynamic and hydrodynamic flow control and the development of novel actuation technologies. The laboratory houses a large-scale (1 x 1 m test section, maximum speed 40-80 m/s) open-return high-quality wind tunnel, a smaller scale (25 x 47 cm) closed return wind tunnel for detailed optical diagnostics, a transonic open-return continuous wind tunnel (nominally M = 0.75 at 12.7 x 12.7 cm), and several air jets. For dynamic experiments, airfoil or wing models equipped with flow control actuators can be mounted on a programmable, 2-DOF (pitch and plunge) traverse in the large-scale wind tunnel. The traverse is electromechanically driven by a dedicated feedback controller that removes the parasitic mass and rotational inertia of the dynamic support system and of the model. The FMRL also includes several test cells for the development of small scale fluidic actuators for flow control, thermal management, atomization, etc. A 300-gallon water tank is available for small-scale experiments (e.g., buoyancy-driven).

The 7,500 ft2 laboratory is equipped with state-of-the-art facilities and diagnostic equipment for research work in fluid mechanics and heat transfer of internal and external shear flows with specific emphasis on aerodynamic and hydrodynamic flow control and the development of novel actuation technologies. The laboratory houses a large-scale (1 x 1 m test section, maximum speed 40-80 m/s) open-return high-quality wind tunnel, a smaller scale (25 x 47 cm) closed return wind tunnel for detailed optical diagnostics, a transonic open-return continuous wind tunnel (nominally M = 0.75 at 12.7 x 12.7 cm), and several air jets. For dynamic experiments, airfoil or wing models equipped with flow control actuators can be mounted on a programmable, 2-DOF (pitch and plunge) traverse in the large-scale wind tunnel. The traverse is electromechanically driven by a dedicated feedback controller that removes the parasitic mass and rotational inertia of the dynamic support system and of the model. The FMRL also includes several test cells for the development of small scale fluidic actuators for flow control, thermal management, atomization, etc. A 300-gallon water tank is available for small-scale experiments (e.g., buoyancy-driven).

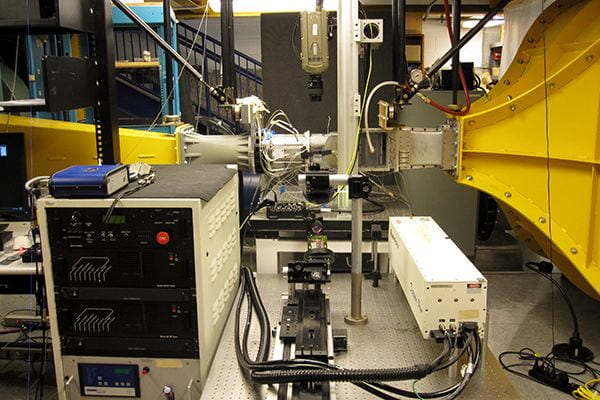

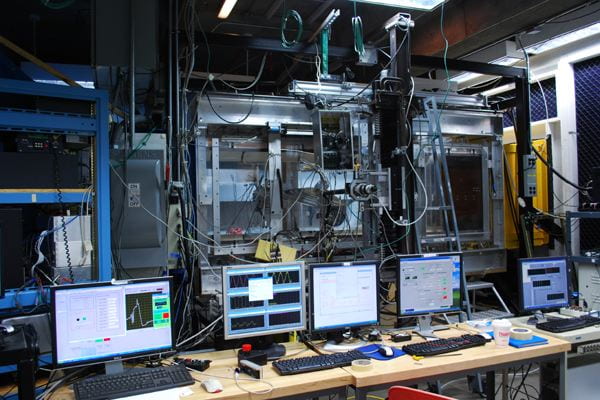

The laboratory is equipped with modern diagnostic equipment including several high-speed data acquisition (A/D, D/A) systems and instrumentation amplifiers, multi-channel hot-wire anemometers and cold-wire thermometers. Optical diagnostic equipment includes DPIV systems (two stereo and two high-speed PIV systems) for measurements of scalar concentration fields, a laser vibrometer, two high-speed (up to 100,000 fps) video imaging systems, and an infrared video system, and a Vicon MX Motion Capture and Analysis System.

Processing for PIV and other data is accomplished using a central network-based high-speed “farm” server. General-purpose instrumentation includes high-voltage amplifiers, multi-channel thermal sensor data acquisition, and high-frequency cold-wire thermometers. The laboratory also includes a station for the development and testing of novel flow control actuators (piezoelectric, electromagnetic, and combustion-based) and acoustic transducers.

A 1200 sq. ft Thermofluidics Laboratory is part of the Fluid Mechanics Research Laboratories at the Woodruff School. The Thermofluidics Laboratory is equipped with state-of-the-art facilities and diagnostic equipment for research work in actively-controlled single- and two-phase heat transport phenomena and thermal management. The laboratory includes a number of modular heat transfer cells, submerged boiling and atomization processes, and several small-scale wind tunnels. Flow loops with remote heat exchangers and constant temperature baths are also available. The laboratory also has specialized bio-fluidic systems for investigations of cardiovascular elements and bio-reactors. Optical diagnostics include stereo and micro-PIV hardware.

Gallery: